Comparing Refacing Materials

by Ray Horsley • January 04, 2019

Refacing your existing kitchen cabinets is a cost-effective means of changing the look of your room. Only painting or refinishing costs less. Some local home centers stock refacing materials, including doors and drawer fronts, but you will probably find a larger selection of higher-quality materials at refacing suppliers, many of whom do business on the Internet.

Selecting Doors for Kitchen Cabinets

Slab doors are the only style suitable for direct application of veneer or laminate. If you have any other style, you'll have to order replacement doors and drawer fronts. Choose replacement doors by following the same general method you would if you were purchasing new cabinets. Choose the material Slab doors are the only style suitable for direct application of veneer or laminate. If you have any other style, you'll have to order replacement doors and drawer fronts. Choose replacement doors by following the same general method you would if you were purchasing new kitchen cabinets.

Wood Veneer for Refacing Kitchen Cabinets

Wood veneer is real wood, sliced from logs in thin layers (about 1/40 inch thick). Veneer adhered to a paper backing is available in both unglued and pre-glued sheets. Sheet sizes are commonly 2x8 feet, but some manufacturers make 4x8-foot sheets. The larger size might result in less waste but can also prove difficult to handle in small work areas. You can easily reface most kitchen cabinet surfaces using the smaller sheets.

Veneer itself is rather fragile, but properly adhered, it is as strong and durable as its substrate (in this case, your existing cabinets). And if severe damage requires replacement of a piece, it's difficult but not impossible to remove. Pre-glued veneer is slightly more expensive, but its convenience is worth the added expense. A newer self adhesive product is even better.

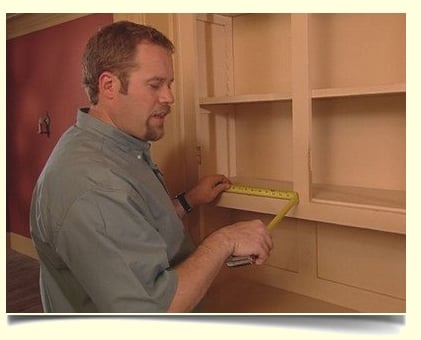

Application starts with cutting the sheets slightly oversize, aligning them, and adhering. Unglued sheets require application of contact adhesive-either sprayed or brushed on- to both the kitchen cabinet and veneer. Pre-glued products may have a hot-glue backing that softens as you apply it with a household iron. Or they may have pressure-sensitive adhesive protected by a removable paper backing. Pressure-sensitive veneer is self-sticking. The newest generation of this product no longer needs any help from contact adhesive to form a stronger bond. Self adhesive veneer is now the best and easiest product to use for stiles and rails. Once applied it can be trimmed by hand with a razor knife or a small router.

Refacing the Sides of Kitchen Cabinets

The end stiles (the vertical members) slightly overhang the sides on most kitchen cabinets. The thin sheets of veneer will not make up the difference, so you must make the surfaces flush. You can either trim the stile with a plane or router, or build up the side with plywood or other material.

- Plywood Pre-cut Panels: The least expensive and best way to cover kitchen cabinet sides is with 1/8 inch or 1/4 inch-thick plywood with one good hardwood face. The thinner stock cuts more easily, but you may find it doesn't lie as flat. Whatever thickness you apply, choose a hardwood and a grain pattern that matches your veneer. Pre-finish the plywood to match the color and final finish of the kitchen cabinets. Fasten it to the sides of the unit with construction adhesive and brads. Local home centers may carry plywood of sufficient quality for refacing. If yours does not, order it from a refacing specialty outlet.

- Phenolic Veneer: This wood veneer bonded to a 4x8-foot sheet of plastic laminate is stiffer than plywood and somewhat more difficult to cut and work with. It easily hides surface imperfections in the kitchen cabinet sides. Apply it with contact adhesive. Its 1/16 inch thickness makes it too stiff to wrap around the edges of kitchen cabinet frames.

- Three-Ply Veneer: This material has three layers of wood and no paper backing. It cuts more easily than other materials and installs with contact adhesive.

Plastic Laminates for Refacing Kitchen Cabinets

Plastic laminates are made from layers of Kraft paper impregnated with plastic resins and bonded together with heat and high pressure. The result is a sheet about 1/16 inch thick that is hard, stain-resistant, and easy to clean, but is brittle and easy to chip. Laminate comes in a wide variety of colors and textures. Solid-color laminates, which are slightly more expensive, do not reveal a brown edge when trimmed.

If you are considering this method of remodeling, we can help you.

Visit our DIY refacing store.

overall rating: my rating: log in to rate